Industrial IoT Data Storage: High-Volume, Low-Latency, Sovereign Storage in Finnish Bedrock

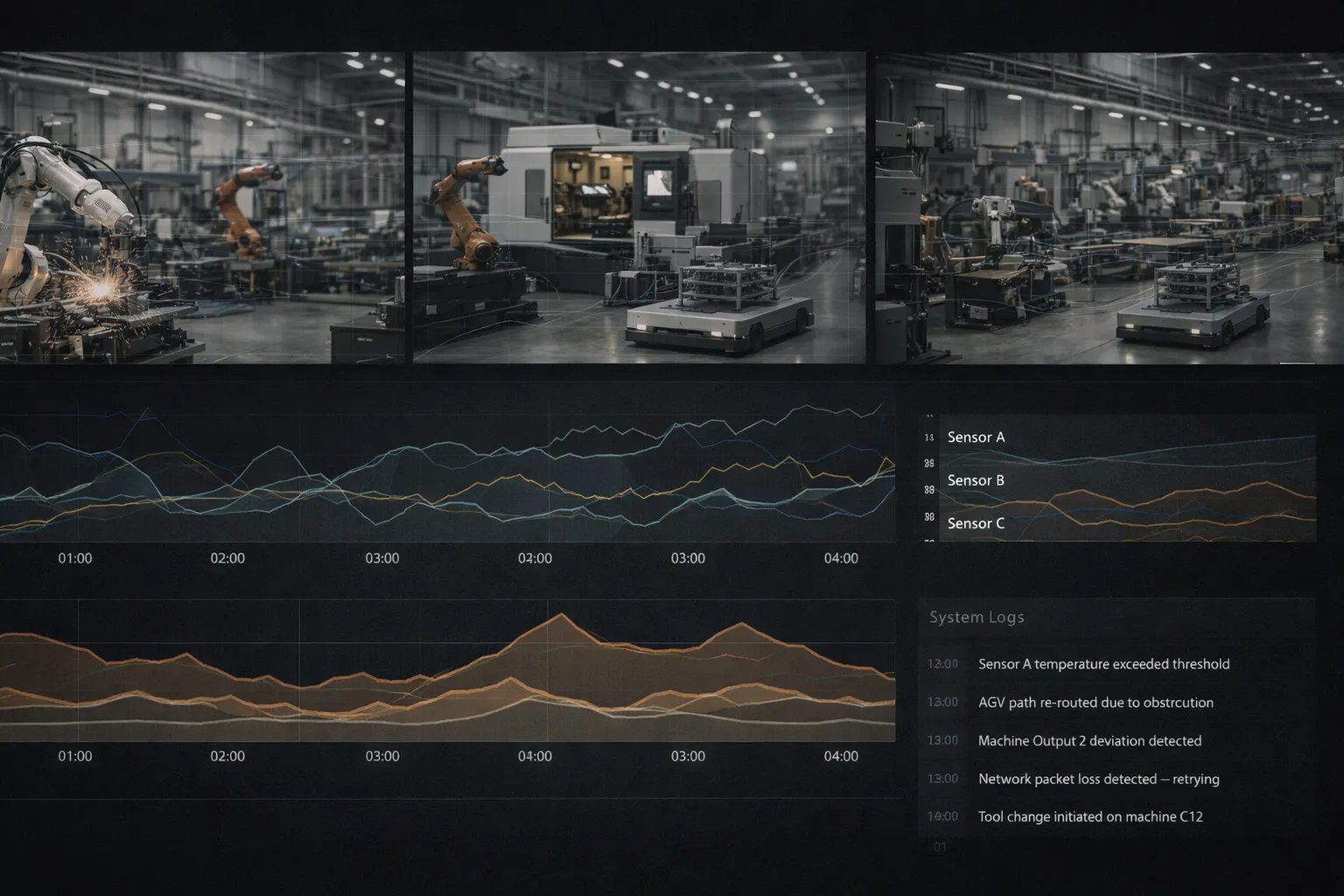

Industrial IoT (internet-of-things) has become essential to many businesses today. As a result, it generates data continuously and relentlessly. Sensors, machines, vehicles and automation systems produce a constant flow of telemetry, logs, images and video. That creates challenges for how to store the outputs effectively.

In the early stages, a cloud bucket and a few dashboards may work well enough. But once your deployment grows past tens or hundreds of terabytes, the reality becomes harder to ignore. Cloud fees compound, egress costs become unpredictable and long-term retention starts to hurt your budget more than the hardware itself.

It’s a relentless cycle because industrial environments don’t stop. They cannot afford storage systems that are slow, noisy, expensive or dependent on global network paths. They need reliable write performance, stable latency, transparent pricing and, above all, sovereign control of their data.

That’s where SpaceTime comes in.

Our storage is purpose-built for high-volume Industrial IoT storage with its time-series telemetry, machine diagnostics, operational logs, maintenance data and video streams.

Our data centre is located within hardened bedrock in Finland, it is physical and can fully integrate with your infrastructure. That means you get predictable capacity, long-term durability and freedom to scale without vendor lock-in or surprise costs.

Whether your footprint is 100 TB, 500 TB or already moving into petabyte territory, SpaceTime provides a stable, sovereign and cost-efficient foundation for long-term IoT data growth.

There’s no egress fees or performance variability. Just predictable, durable, industrial-grade storage designed for real deployments, not theoretical architectures.

Request a Quote

What Is Industrial IoT Data Storage?

Industrial IoT data storage encompasses the systems and processes that collect and preserve data generated by industrial devices.

These include sensors, PLCs, robotics, cameras, vehicles and distributed automation systems across factories, warehouses, energy grids or transportation fleets.

Unlike traditional IT data, IoT data is continuous, high-volume and geographically distributed. It is write-heavy, often millions of events per hour, highly time-series-oriented and generated 24/7. It is also operationally critical, legally sensitive and rarely deleted.

Storage becomes a foundational part of the long-term architecture, not an afterthought. All of the following require storage that can absorb continuous ingestion while offering long-term durability.

Industrial IoT data typically falls into four categories:

- Telemetry and time-series measurements: tiny individual data points that become massive in aggregate.

- Operational and machine logs: produced in bursts but retained for years for diagnostics and maintenance.

- Images and video streams: the fastest-growing category, pushing deployments into petabyte scale.

- Compliance and audit data: this must remain immutable and accessible for long periods.

Why Industrial IoT Storage Is Different From Traditional IT Storage

Industrial IoT brings challenges that public cloud storage handles poorly at scale.

The first is ingestion rate. IoT systems write constantly. Many cloud services are optimized for occasional writes so they stall or throttle under sustained load.

The second is architecture. Industrial systems generate data at the edge but analyze centrally. Moving large datasets through limited or expensive network paths introduces latency and bandwidth constraints.

Third up, retention matters. IoT data often needs to be stored for a long period that could span five to twenty years, depending on industry and regulation. IoT workloads are also predominantly write-heavy and low-read. Most data is written now, read later. Sometimes much, much later. Public clouds are priced and engineered for the opposite pattern.

And finally, sovereignty requirements are increasingly non-negotiable. Many industrial customers must ensure their data stays in-country, encrypted at rest and physically protected in a facility they can trust.

The cloud does not guarantee full sovereignty. That’s why many organizations begin migrating off-cloud once their IoT footprint crosses 50–100 TB.

How Industrial IoT Data Storage Architectures Work

A complete IoT storage pipeline typically involves three layers:

Edge storage sits close to the device. It handles low-latency analytics, situations where connectivity is limited, data pre-filtering and immediate safety logic. It does not replace central storage, instead it reduces unnecessary transport.

Hot or near-hot storage supports real-time dashboards, 24–72 hours of raw data and short-term analysis. Time-series databases and streaming systems live here.

Cold or deep storage is where more than 90% of IoT data eventually resides. This includes raw event history, diagnostic logs, video archives, maintenance data and compliance records, all of which is kept for years.

This is the layer Spacetime optimizes. We provide 100 TB to multi-petabyte volumes stored efficiently, reliably and cost-predictably.

Where Cloud Storage Fails for Industrial IoT

Cloud vendors provide impressive scalability, but real deployments quickly reveal the trade-offs.

Egress fees turn success into a liability. Retrieving your own data becomes expensive, especially when analytics workflows require bulk export.

Long-term retention costs balloon once you account for redundancy, access frequency and regional replication. Storage performance is not consistent under high ingestion load. Clouds are not engineered for sustained industrial write throughput.

Vendor lock-in becomes painfully visible when trying to move hundreds of terabytes out of a region. Plus, sovereignty remains uncertain since a geographically located region is not the same as sovereign control.

For many industrial deployments, these limitations are incompatible with operational requirements.

Why Sovereign, Off-Cloud Storage Works Better

SpaceTime offers a fundamentally different foundation for Industrial IoT data.

Data is stored inside hardened Finnish bedrock, which is a sovereign, physically resilient environment that’s designed expressly for stability.

You get predictable performance, controlled access and fixed pricing with no egress fees. There is no dependency on hyperscaler networks or pricing policies. You maintain your existing architecture while gaining reliability and cost clarity.

This model is particularly critical for industrial automation, energy networks, transportation fleets, manufacturing, smart cities and security environments. Any place where data is mission-critical and long-term retention is a certainty

When Should You Move IoT Data Off the Cloud?

Most organizations begin shifting storage off-cloud when they encounter one or more thresholds.

It could be when data volumes exceed 100 TB, egress fees creeping past €1,000 per month, long-term retention mandates, continuous video generation, sovereignty requirements or unpredictable monthly bills.

Write-heavy workloads slowing under cloud throttling is another common trigger. For many, hybrid architectures become necessary, making an off-cloud storage foundation even more attractive.

SpaceTime follows a simpler model.

We offer a fixed cost per terabyte per year, with no egress fees, no retrieval charges, no lifecycle management rules and no unpredictable spikes.

We are predictable, sovereign and engineered for long-term retention.

How Spacetime Stores Your Industrial IoT Data

SpaceTime’s storage platform is engineered for one purpose: long-term, high-volume, high-integrity data retention at industrial scale.

Under the hood, DataOcean is built on Ceph, the industry-leading open-source storage platform trusted by major enterprises and maintained by IBM. It runs on standardized, modular hardware designed without single points of failure, duplicate power, cooling and networking across the entire stack.

To ensure durability at petabyte scale, DataOcean uses 16:4 erasure coding, a configuration that can automatically recover from up to four simultaneous disk failures and provides a statistical durability of eleven nines (99.999999999%). This is the level of fault tolerance industrial IoT workloads require when data is continuously ingested and rarely deleted.

Our connectivity includes public internet, Megaport dedicated bandwidth from other providers or custom mobile APN for secure mobile connections.

The physical infrastructure where DataOcean is housed runs on 100% renewable energy and has the following physical, operational and environmental certification: ISO 27001, ISO 9001, ISO 14001, PCI DSS, KATAKRI, PAS 2060 Climate Neutral.

Applications Across Industry

Manufacturing environments rely on machine telemetry, predictive maintenance datasets and camera-based quality control systems. Energy and utility providers generate turbine logs, solar inverter data, grid telemetry and consumption metrics.

Logistics and transportation fleets capture sensor data, vehicle telemetry, video and cold-chain monitoring records. Smart buildings and cities produce environmental readings, HVAC analytics and extensive security archives. Industrial automation systems generate PLC logs, SCADA events and robot telemetry.

Wherever devices operate continuously, they generate data continuously. SpaceTime provides the sovereign and durable foundation needed to store it. We do it at scale, without surprises, and without slowing your operations down.